- Insight

- March 15, 2024

The benefits to industry of investing in sustainable innovation

Reducing operating costs, improving reputation, increasing revenues, consolidating partnerships. These are just some of the benefits experienced by companies that have invested in sustainable innovation and were surveyed in the “State of the Green Economy Report” published in 2022 by Foundation for Sustainable Development in collaboration with EY. Responsible for about 25 percent of Italy’s total emissions (Istat, 2021), there is no doubt that investments in emissions reductions by manufacturing companies are essential to address the climate crisis. Investing in innovative decarbonization pathways is a strategic choice that brings competitive advantages and new growth opportunities to the companies themselves.

In this article we will explore the benefits of implementing production process efficiency solutions and try to bring some concrete examples.

If interested in learning more follow our Linkedin page for all updates.

Reduction in operating costs

“Corporate social responsibility is to grow profits,” was the headline in a controversial New York Times article written by famed economist Milton Friedman in 1970. If it was meant to be a provocation at the time, after a few decades, with the development of technology and an ever-present climate crisis, we are (finally) forced to reconsider our patterns and priorities. However, the good news is that the size of business and the size of sustainability do not grow differently in proportion. Investing in energy efficiency, process circularity, emission reduction and eco-design enables companies to increase their profits.

In the research conducted by EY and Foundation for Sustainable Development cited earlier, among the benefits found by companies are reported precisely: reduced production costs and increased revenues. From our experience, we can confirm that the implementation of Green-Tech technologies in companies’ production processes has an impact on more efficient use of resources and a consequent reduction in costs. Here are some examples based on real experience:

-

implementation of an AI-based monitoring system can provide a metallurgical company with energy savings of between 4 percent and 15 percent.

-

stabilization of incoming electricity through power quality can bring a 6 percent savings in electricity consumption in a plastic molding company.

-

investment in compressed air management system optimization can enable savings of up to 40 percent in multiple sectors.

The important aspect that companies need to take into account when evaluating these simple investments in process efficiency is that the average payback time is very low at about 3 years. This means that as early as the fourth year these efficiency choices will have a significant positive effect on the income statement. Moreover, the examples given represent only a tiny fraction of the set of interventions that can be implemented in manufacturing companies, with sometimes significantly greater positive effects on the income statement.

Sustainability as an element of customer value

Whether your company operates in B2B or B2C, one thing is certain: your customers are becoming more environmentally conscious. When investing resources for decarbonization projects, it is important to communicate that commitment transparently and creatively to gain reputational and image advantage.

B2B

Those working in B2B cannot have failed to notice increasing pressure from large companies on their suppliers to reduce the carbon footprint of their operations. This is mainly due to the European regulatory pressure faced by large or particularly energy-intensive companies. These companies are required to take environmental responsibility and action throughout the Supply Chain (Purpose 3 emissions). As reported in a 2022 Carbon Disclosure Project report, 75 percent of large global companies have imposedCO2 emission reduction targets on their suppliers. In addition, 63 percent of companies said they would cancel contracts with suppliers who do not meet emission reduction targets. Having more sustainable processes is becoming a criterion of choice for large companies and an essential element for staying within the market.

STEP recently partnered with Decathlon Italy to support suppliers in moving toward greater circularity of processes, we had discussed in this post.

B2C

At the end of the value chain of a production sector we find the end consumer. The National Observatory on the Sustainable Lifestyle of Italians conducted by Lifegate in 2022, reports that 23 percent of consumers are willing to pay more for a product deemed sustainable. This figure is interesting because price represents the monetization of the value an asset takes on for an individual person. A higher price, indicates a higher perception of product value. In this case, the sustainability characteristic affects the perceived quality of the product itself. But if we reflect, this is extremely logical, in fact a product that is designed to last longer over time, using raw materials more efficiently, reusing waste, and following the rules of eco-design is objectively a higher quality product.

Innovation and results

When we talk about environmental sustainability in STEP, we most often refer to decarbonization pathways based on the internationally recognized process of:

-

Calculation of one’s impact

-

Reducing emissions

-

Offsetting of non-reducible emissions

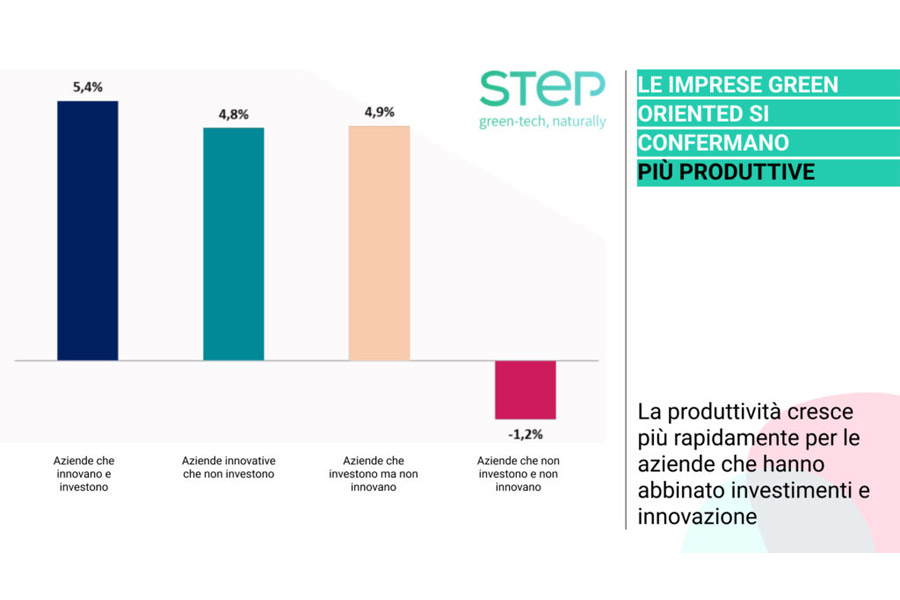

The message that we are interested in remaining indelible to those who are reading this article is that investments in environmental sustainability bring excellent results (structural results) in terms of business only when working on point 1 (impact calculation) and point 2 (actual impact reduction). Environmental sustainability, more than a concept, something that can be inserted or removed from corporate strategy, that is there or not, is an approach, a modus operandi. Doing sustainability in business means being aware of your process and its impact on the environment, knowing it thoroughly and taking action to make it more efficient and less impactful in terms of emissions, raw material use, and waste generation. Innovation is the tool to achieve these goals. In decarbonization pathways structured with our clients, we often include innovation workshops to help companies look for alternative solutions, change views and priorities, and ask the right questions. In this way the company is able to remain competitive in the market as we demonstrate the following data.

Cerved, 2019