- Events

- April 17, 2024

5 tips for innovating industrial processes sustainably: insights from Parma Green Week

On April 5, we were guests on the panel ” Decarbonization starts from the heart of the problem: sustainable innovation of industrial processes,” held during Green Week in Parma, the green economy festival. We decided to summarize in this article the points that emerged from the discussion with Gr3n, an innovative startup, and the companies Conceria Montebello and Rigoni di Asiago. Companies that have embarked on a path to reduce their environmental impact through process innovation work and can be an inspiration to other industries that want to move closer to a responsible business model.

1. Measuring to Innovate

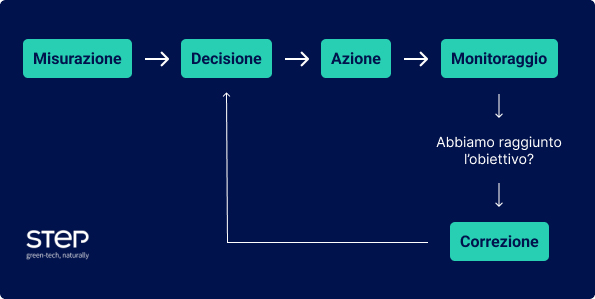

The first key pillar that emerged during the event is the importance of “measuring” production processes: as Giuseppe Fongaro of Montebello Tannery pointed out, before being able to innovate, it is essential to spend time in-depth understanding of every aspect of the production process. Measurement is not a one-time activity, but requires an ongoing commitment over time. In fact, monitoring the data collected makes it possible to identify areas for improvement, operate by objectives and evaluate the effectiveness of the actions taken, following a virtuous cycle that can be summarized as: measurement, decision, action, monitoring and, if necessary, correction.

Figure 1-Innovative approach

If you are thinking about reducing the impact of your processes, our advice is to start with an

assessment

to get a mapping of impacts, thus identifying areas for action.

2. Innovate Step by Step

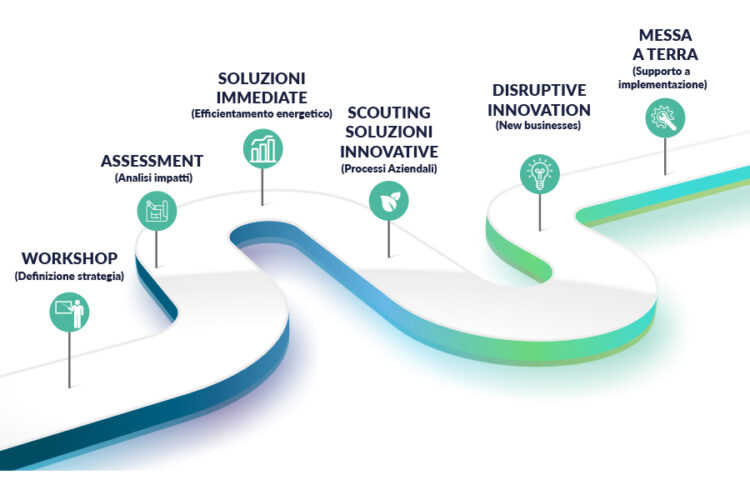

Industrial process innovation requires a step-by-step approach. Our business developer manager, Loredana Reniero, shared our daily experience with industrial companies that decide to innovate processes from a sustainable perspective. The typical path usually starts with energy efficiency in the plant. This initial step, which normally has no impact on the production process, allows for initial economic, as well as environmental, results and greater awareness with respect to the potential of sustainable innovation. The next step is process innovation through the search for alternative technological solutions to those traditionally used, to achieve an impressive reduction in environmental impact. The last step, the most creative and delightful one that can lead to more disruptive results, involves completely redesigning industrial products, processes and machinery through Open Innovation in a sustainable way.

Figure 2-Sustainable innovation path of STEP

Loredana Reniero also pointed out in her speech the main barriers to innovation that she finds in the path of shadowing industrial companies:

- Cultural barrier and sense of bewilderment: some companies feel disoriented in the face of the volume of activities needed to make their businesses more sustainable. It must be remembered, however, that the innovation process is a gradual path, which does not involve an immediate upheaval of the production process, but is calibrated to the needs of the company, combining areas for improvement with solutions best suited to its situation

- Focus on the wrong target: many companies focus on ancillary activities and not on the heart of the problem: the production process. This wastes resources and energy on activities that do not solve the root problem. A classic example is the activity of planting trees in the area, which is an absolutely positive activity, but incidental to the company’s main environmental impact.

- Lack of vision: a common mistake is to approach sustainable change by focusing on the short term, in doing so we focus solely on the cost and not the investment. Many companies, unfortunately, do not see the economic return in the medium to long term of process innovation projects, thus missing important opportunities.

- Waiting for the perfect solution: the renowned speed at which technology runs brings with it a common fear of investing in a tech that, in a short time, may be replaced by a new, higher-performance solution. This fear leaves companies in a stalemate, leading them to never innovate, thus losing competitiveness.

3. Finding the right KPIs: beyond turnover

Beniamino Perobelli, CSR manager at Rigoni di Asiago, highlighted how, in an era of profound change, mere turnover or margins can no longer be considered the only indicators of success for a company. In addition to economic performance, other parameters become crucial: emissions reduction, renewable energy use, process efficiency, packaging sustainability, and transportation efficiency. That said, acting sustainably not only reduces environmental impact but also results in immediate economic benefits through reduced operating costs and, in the medium term, through improved market reputation. The importance of sustainability KPIs is also demonstrated by the attention the European legislature is giving to the issue with the CSRD directive, which elevates non-financial reporting to the same level as financial data, making them interdependent.

4. Working as a team to innovate

A cross-cutting theme that emerged from the discussions was the importance of governance and alignment within the company. Innovating with a view to sustainability requires a cultural change that sees sustainability not as a cost, but as an investment that enables an opportunity for resource efficiency and optimization. Beniamino Perobelli’s experience with Rigoni di Asiago and Giuseppe Fongaro’s experience with Conceria Montebello highlight how support and engagement at all levels of the organization are critical to the success of these initiatives. Those involved in innovation must strive to “transfer the value of change to their employees.”

5. Eliminate the word impossible

We conclude with a reflection to question our approach to innovation from the perspective of those who develop technological solutions.

“For 100 times the word impossible was inappropriate,” says Maurizio Crippa, CEO of GR3N SA, a startup that has developed an innovative chemical recycling process for PET. “Impossible,” this word represents one of the main challenges to innovation in Italy: resistance to change. The method developed by GR3N introduces a circular model that allows PET recycling from bottle to fabric, fabric to fabric, and even fabric to bottle. This technology addresses an urgent need for sustainability at a time when the debate over textile waste is more heated than ever. Despite this, solutions that could alleviate key problems in our manufacturing system are struggling to find support from those who would directly benefit: industry. Developing innovations of this caliber is complex and requires years of research and significant investment-in this case, 10 years of work and 25 million euros in funding. Innovations that really make a difference do not emerge overnight, and while technical and economic barriers may be more complex to overcome, cultural resistance is a detrimental but not insurmountable obstacle. Our invitation is to think 10 more seconds before responding “impossible” to innovation proposals.

All the speeches were really very interesting and enriching, if you have an interest in learning more about this topic, we invite you to relive the event at this link:

https://www.youtube.com/watch?v=_KIpDdQ9p9E

For all updates, follow us on our Linkedin channel